Full service metal

End to End Metal Engineering and Fabrication Service

We work in partnership with our customers to deliver metal solutions for a variety of sectors such as mining, construction, food processing, agricultural, automotive and furniture manufacturing. Here we showcase a number of products we manufacture on a regular basis to high standards for a variety of customers. Products such as: battery racks, battery enclosures, transformer enclosures, hot aisle containments, trolleys and dollies.

Privacy Screens

At Alliance Metal, we have the capability and know-how to manufacture large quantities of screens for multi-residential property development projects. We user our Yawei fibre laser cutting machine to cut any pattern required to suit a project. Powder-coating is also completed in-house with a wide variety of colour options available.

Hearing Test Booths

Alliance Metal Solutions has an ongoing contract to manufacture a range of sound proof hearing booths for an Australian hearing specialist company. These booths get installed into retail outlets, hospitals and other centres throughout Australia.

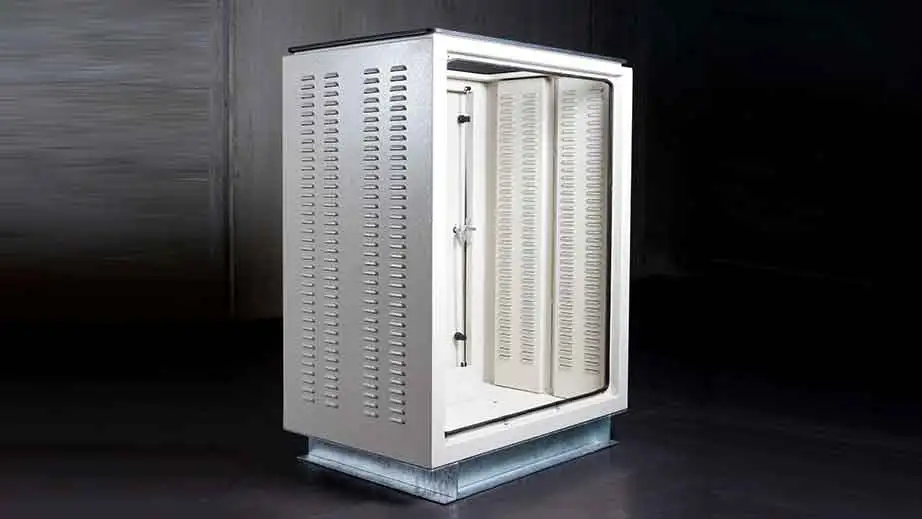

Transformer Enclosures

Custom designed for various switchgear/transformer shapes and sizes, our enclosures are suitable for indoor or outdoor use, with a removable cover for access if required or front door panel. Our enclosures are vented to allow heat escape from the transformers to evaporate, whilst still allowing them to retain their IP rating. Enclosures can be made from mild steel and powder-coated.

Battery Racks and Cabinets

Alliance Metal Solutions work within the ISO 9001 quality accreditation frame work. We manufacture a variety of custom made UPS battery racks and cabinets that have been completed load tested for safety purposes. We can make to all requirements and sizes of easy to use racks that are strong, flexible and powder-coated.

Hot Aisle Containments (server rooms)

We manufacture HAC spaces for various customers and have the knowledge and know-how to make this to suit your requirements. Hot aisle containment consists of a physical barrier that guides hot exhaust airflow back to the AC return. Hot aisle containment (HAC) takes advantage of the natural properties of warm air rising. The HAC system directs the upward airflow to an AC return system such as a drop-ceiling void. To have HAC spaces made, speak to a member of our team about your specific needs.

Frequently Asked Question

This is very product, material and design dependent based on how complicated the piece is but an average process would be 4 weeks, from minor design changes to prototype.

Yes we do. We have customers in Canada, Singapore, and other countries.

Suspendisse dapibus ligula a ligula luctus, quis We use Solid Works and CAD