Turret Punch

Extensive capability in sheet metal perforation from an expert in turret punching with a fleet of CNC

punch press machines.

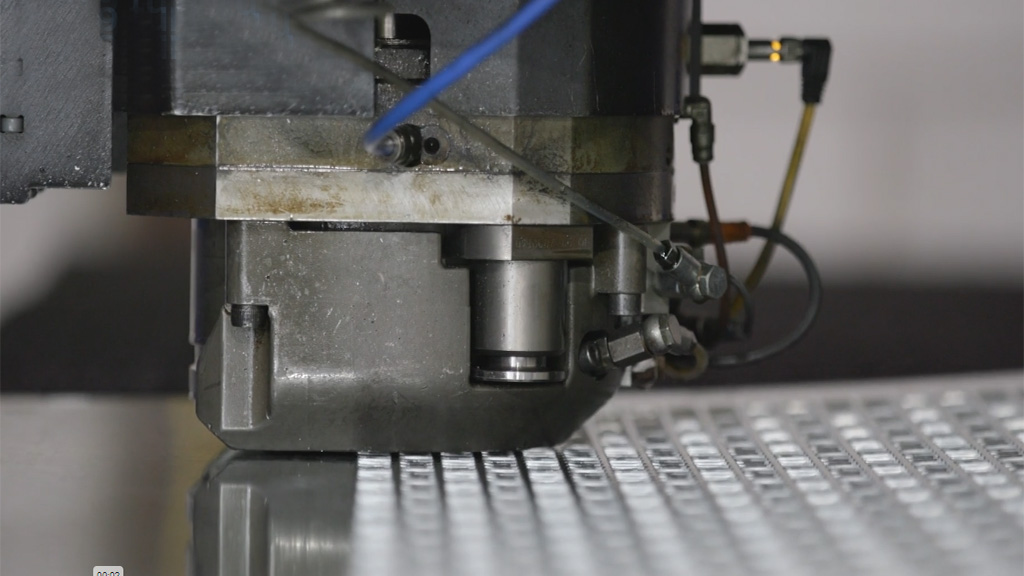

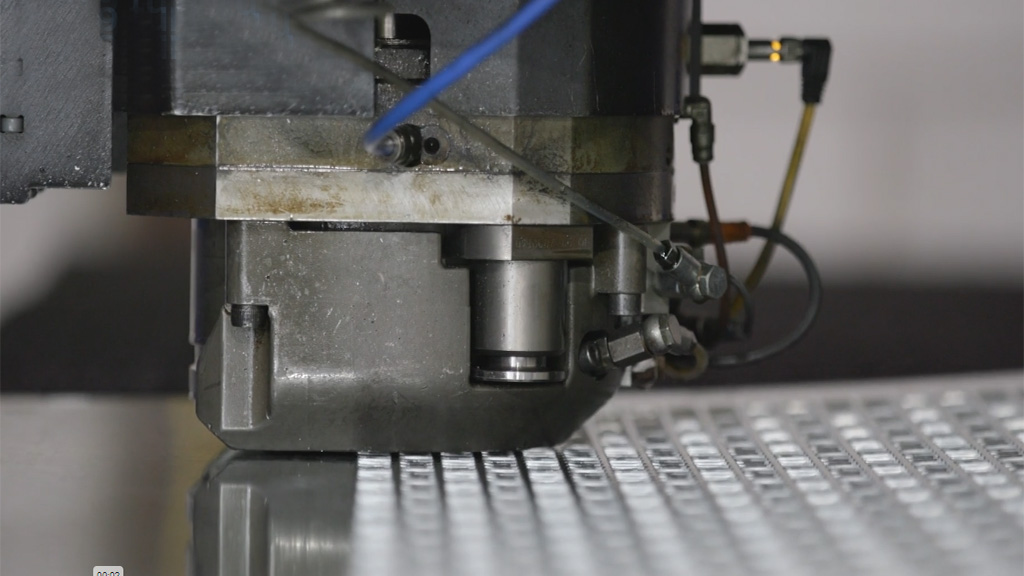

Automated Turret Punch Machine

We have a vast array of tooling for our automatic turret punch machines which can operate 24hrs a day, 7 days a week.

CNC Punch Press Services

When you’ve been fabricating perforated sheet metal solutions by turret punching as long as Alliance Metal Solutions (AMS) has, you get pretty good at it.

Since 2007, AMS has been fabricating perforated and formed sheet metal products on our fleet of in-house turret punch machines for commercial and government projects Australia wide. In this time, we have amassed an extensive tool library enabling fabrication of a vast number of perforation and form patterns including different shapes, aperture, pitch and open areas.

With our fully automated equipment, including self-loading and unloading functionality, we run a lights out system enabling production 24 hours per day 7 days a week. This means we can fabricate perforated sheet metal projects within competitive lead times for short or long run projects.

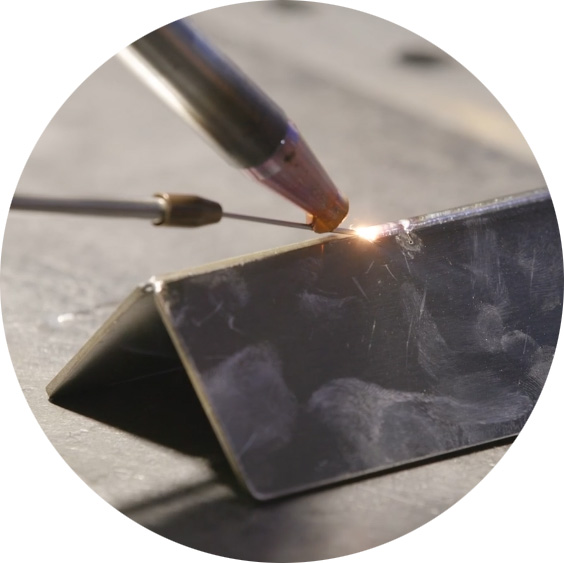

Our CNC punch press sheet metal solutions can be manufactured as stand-alone components. Or, with our diverse range of other services, can be further fabricated with bending, welding, SHS / RHS framing, assembly and finishing with powder coating or galvanising.

Our Turret Punching Solutions

At AMS, we continually invest in our equipment and the skill of our operators to enable quality production within competitive lead times.

Our fully automated CNC punch press machines run multi-tool stations with total capacities ranging from 31 stations to 45 stations. Our turret punch machines process a range of metal materials, including

- aluminium

- stainless steel

- mild steel

- galvabond

- zinc anneal

in material thickness from 0.5mm up to 5mm.

Working with sheet sizes up to a maximum single sheet dimension of 1200mm x 3600mm, we fabricate to the custom panel dimensions required for each project.

Our range of tooling includes

- cluster punch tools

- single punch tools

- form tools

in various shapes including

- round

- square

- hexagonal

- rectangular

We can fabricate to an extensive range of aperture enabling fabrication of a vast number of patterns with varying pitch and open area. We can also fabricate patterns requiring a combination of shapes and varying perforation arrangements of hole size, aperture and pitch on a single panel.

WHAT TO EXPECT

Leading Experts in Perforated Sheet Metal

We know the precision and quality of our fabrication is critical to your project.

At a project’s beginning, our experienced team work with your technical drawings to program fabrication and schedule production. Our processes ensure the end product meets the exact specification and is delivered within the committed lead time.

At this stage, we can also put our extensive industry experience to work creating additional value for our customers. Leveraging our expertise in design and fabrication, we can advise on opportunities for product design enhancements to achieve a range of benefits. These including more effectively achieving the product objectives, specifications and functional requirements, as well as optimising design for more efficient and cost-effective fabrication to reduce the overall cost and lead time.

At every stage from the beginning of a project to the despatch of the completed product, our embedded quality management system ensures our quality fabrication. Evidenced by our ISO9001 accreditation and overseen by both our Production Manager and Quality Assurance officer, quality checks are completed at each stage of fabrication to continually monitor production to our standard of quality.

You can rely on us to deliver your perforated metal requirements within the lead time we say we will. Because of our experience, we will accurately quote lead times up front.

And, because we manage all fabrication in-house and invest in multi-skilling our team, our production team leaders and our hands-on owners can flexibly resolve bottlenecks and prioritise workflow to ensure we deliver on time.

Our Services Beyond Turret Punching

Fabricating perforated and formed sheet metal solutions for end use here in Australia and around the world, AMS provides sheet metal engineering services to a wide range of industries including construction, mining, public infrastructure, energy, telecommunications, agriculture, transportation, health care, hospitality and automotive.

Our range of end-to-end metal fabrication services encompassing Design Services, Tube Laser Cutting, Flat Bed Fibre Laser Cutting, Turret Punch Service, CNC Bending Services, Welding, Powder Coating, and assembly enables us to provide complete fabrication solutions.

Get In Touch

Request A Quote

Acknowledgement of Country

Alliance Metal Solutions recognises the Darug people as the Traditional Owners of the land on which we work. We acknowledge traditional Owners of Country throughout Australia and recognise the continuing connection to lands, waters and communities. We pay our respect to Aboriginal and Torres Strait Islander cultures; and to Elders past and present.